One Drag Four Video Camera Solution

One drag four video microscope 1. Introduction to one-to-four video microscope Features One drag four video microscope is

Complete Industrial Camera Series, meeting all your needs

GigE、USB2.0、USB3.0、10 GigE、Binocular、 Line Scan…..

MindVision industrial cameras can be used in biomedical, logistics, aerospace, semiconductor inspection, transportation, robotics, drones and other fields.

Join the phone:

+86 184 7654 6577

Affiliate mailbox:

GlobalMarket@mindvision.com.cn

We have over a thousand products, including industrial cameras, image acquisition cards and industrial lenses. In the 12 years since our establishment, we have served more than 20,000 customers and sold over one million industrial cameras in total.

One-stop and systematic, enabling full-scenario applications in manufacturing production.

Overcoming core technical difficulties and independently researching and innovating technologies, continuously upgrading the coverage dimension of product applications, providing the market with one-stop AI vision solutions with a high degree of demand matching, meeting 2D/3D vision inspection services, and implementing landing in thousands of subdivided scenarios in different manufacturing industries, such as defect detection, dimension measurement, logistics supply chain, visual sorting, workpiece loading and unloading, etc.

Industries Where Our Industrial Cameras Can Be Applied

The consumer electronics industry is a pillar industry of the national economy. Its high iteration speed makes it face greater challenges in aspects such as design, manufacturing, and quality control. The automated inspection of machine vision can replace manual inspection in production lines such as component inspection, component assembly, and the appearance inspection of complete machines, achieving multiple inspections including those of panels, holes in mobile phone inner shells, cameras, PCBs/FPCs, and assemblies, effectively improving production efficiency and product yield.

The new energy industry represents the new futureof the country’s green economy. With the transformation and upgrading of the manufacturing processes in new energy industries such as photovoltaics and lithium batteries, it is particularly important to achieve automated inspection. Machine vision inspection can not only detect and sort out internal defects and impurities in wafers and battery cells but also test product dimensions, appearance defects and surface quality, strictly controlling product quality and improving production efficiency.

The semiconductor industry encompasses the design, layout, manufacturing, assembly and testing of various semiconductor components and products. Machine vision is mainly applied to production line automation and product quality inspection, including positioning and assembly during assembly, dimension inspection and the detection of defects (holes, scratches, corrosion, ripples, non-uniformity) in finished products, thus realizing the quality assurance of components, assemblies and finished products.

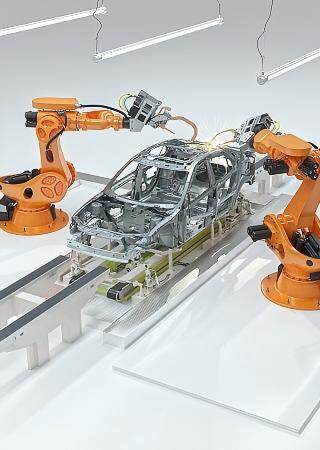

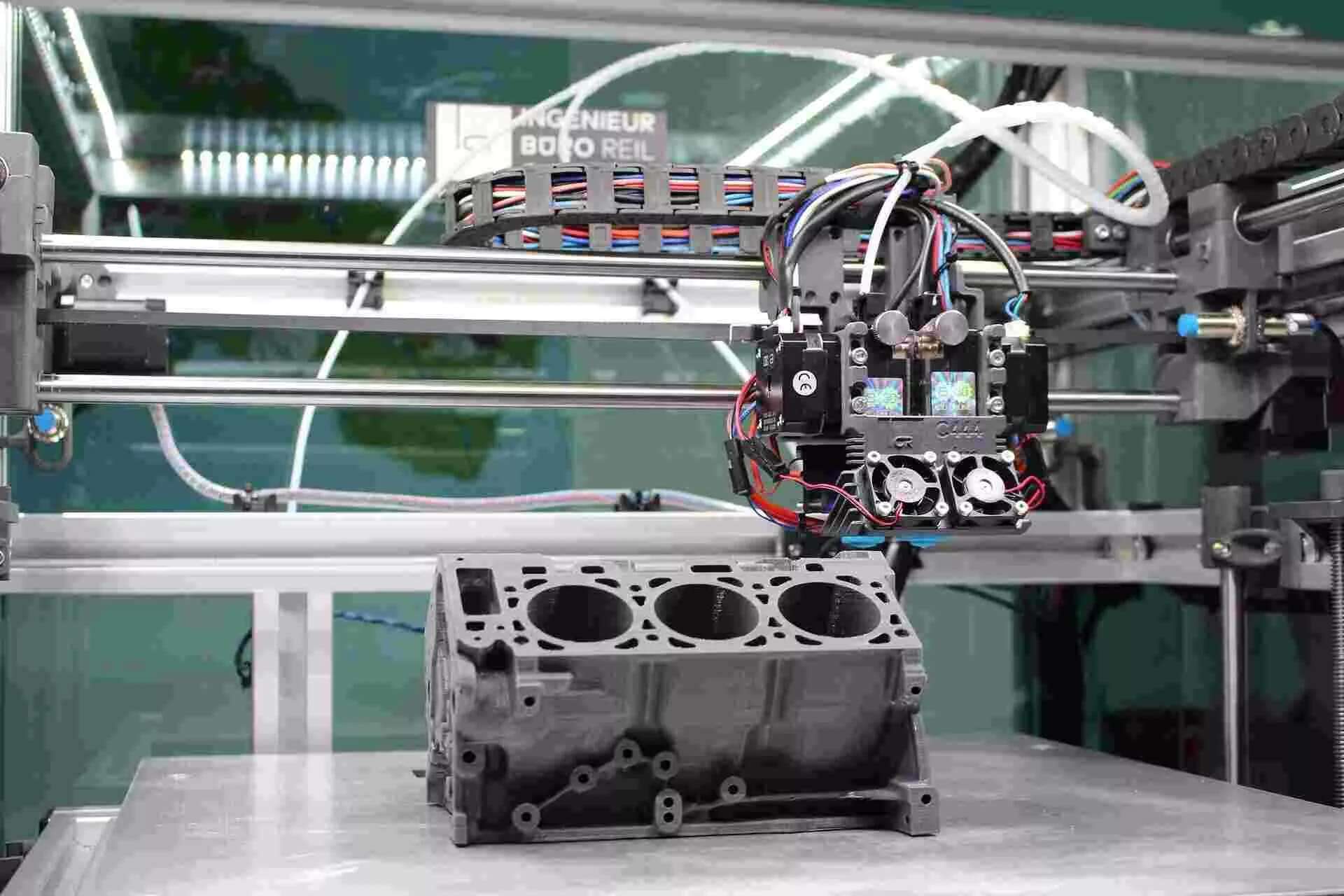

As an industry with a high degree of automation in manufacturing, the automotive industry cannot do without machine vision in every link of production. Machine vision technology can provide reliable guarantees in the stages of automobile manufacturing and assembly such as the inspection of spare parts, the measurement of hole positions, the inspection of castings, the inspection of engine assemblies, spraying, and welding, ensuring the quality of assembled parts and the correctness of assembly, and improving the efficiency of assembly line production and the degree of production automation.

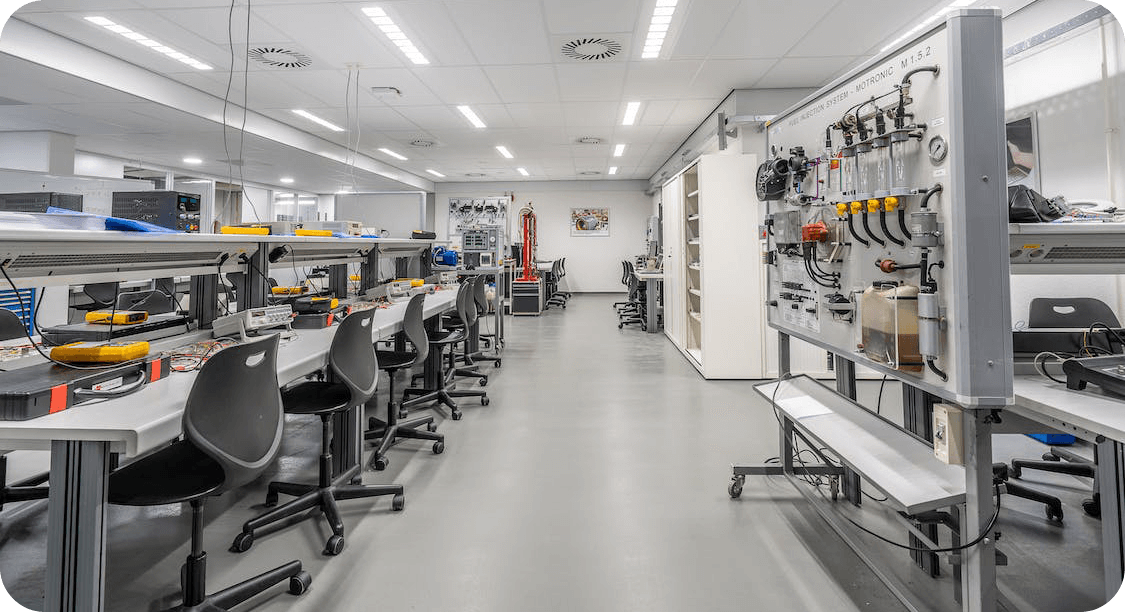

With the popularization of machine vision technology in universities and scientific research institutions, the demand for machine vision teaching and research has been constantly increasing. The machine vision teaching and scientific research experiment system can provide experimental cases for courses such as image processing, pattern recognition, and mechanical inspection, and play an active role in students’ preliminary research in professional fields, in-depth exploration of topics, and project implementation. Scientific research-level products can also provide solutions for high-end scientific research in fields such as physical engineering, life science, and high-precision automation for various universities and scientific research institutes.

As a basic industry for national development, the transportation industry has a significant impact on economic growth and trade. Ensuring the transportation capacity and operational safety of the transportation sector is particularly important. Machine vision technology can be applied in the transportation industry such as tunnel inspection, pantograph inspection, wheelset inspection, highway inspection, and road condition analysis, realizing the dynamic collection, storage, transmission, and early warning of information, and safeguarding the transportation industry.

The pharmaceutical industry is an industry that puts quality first, and it is particularly important to ensure the safety of the pharmaceutical industry. In the field of medical diagnosis, by using machine vision systems to analyze and process medical images, medical examinations for diseases can be achieved, reducing the rate of misdiagnosis and improving the efficiency of diagnosis. Meanwhile, in the pharmaceutical industry, machine vision can be applied in aspects such as the detection of appearance defects of drugs, the detection of defects in blister packaging, and the detection of visible foreign objects and sealing defects in injection and infusion products, improving the efficiency and quality of drug quality inspection.

With the advent of the Industry 4.0 era, machine vision has gradually become an indispensable part of industrial automated production. Machine vision systems have greatly enhanced the information acquisition and processing capabilities in the industrial automation process and have been widely applied in various industries. Besides the classic 3C industry, new energy industry, automotive industry, transportation industry, university research, pharmaceutical industry, etc., it also has extensive applications in industries such as logistics sorting, food processing, mechanical manufacturing, printing and packaging, tobacco, agriculture, and textiles. It can achieve functions like defect detection, trajectory correction, measurement and integrity inspection, grasping and placement, thus promoting the development of industrial automation.

Save you product development costs.

One drag four video microscope 1. Introduction to one-to-four video microscope Features One drag four video microscope is

As a professional camera hardware manufacturer, MindVision can customize camera hardware with deep learning capabilities for various industries,

On the basis of smart cameras, we can add the following functions to make an all-in-one handheld camera.

MindVision, a leading Chinese industrial camera manufacturer founded in 2013, specializes in highprecision imaging innovation. Headquartered in Shenzhen with R&D and production bases in Changsha and Wuxi, its products serve over 50 countries globally.

©2024 Shenzhen MindVision Technology Co., Ltd. Copyright.