Project Background

As an indispensable logistics carrier in modern factories, the significance of turnover boxes cannot be overstated. They not only hold various production materials but also serve as a crucial link connecting all aspects of the production line. However, in actual production operations, our clients face numerous challenges. Due to the heavy weight of turnover boxes, a wide variety of SKUs, and the complex and diverse patterns on the surface of turnover boxes, traditional manual unstacking solutions can no longer meet the needs of efficient and automated production. This not only leads to low production efficiency but also keeps labor costs high. Therefore, clients are eager to introduce advanced intelligent technologies to solve this long – standing problem. This project aims to apply A – intelligence in the industrial field, enabling robots to flexibly identify and handle various turnover boxes of different sizes and patterns, thus achieving automated unstacking, improving production efficiency, and reducing labor costs.

Implementation Plan

- Logistics Cart Transportation: The logistics cart automatically transports the pallet stacked with turnover boxes to the designated position, that is, below the industrial camera.

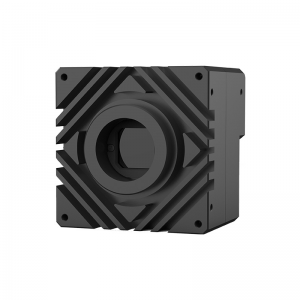

- Photographing and Point Cloud Generation: A high – precision industrial camera is used to take a full – range of photos of the turnover boxes on the pallet, ensuring that the detailed features of each turnover box are captured. Subsequently, through advanced image processing technology, three – dimensional point cloud data of the turnover boxes is generated, providing an accurate basis for subsequent position acquisition and handling operations.

- Position Acquisition and Robot Handling: Based on the generated point cloud data, the system can quickly determine the specific position and orientation of each turnover box. Then, a high – performance robot automatically completes the corresponding handling and unstacking process according to this information. Through precise robotic arm control, the robot can easily handle turnover boxes of different weights and sizes, ensuring a stable and efficient handling process.

- Pallet Removal: After the unstacking operation is completed, the pallet loaded with empty turnover boxes is automatically transported out by the logistics cart, ready for the next round of material feeding and transportation tasks.

Project Results

- High – efficiency Automation: The robot can complete the unstacking operation of a whole stack of turnover boxes within 2 minutes, greatly improving production efficiency. At the same time, the 24 – hour non – stop working mode further increases the overall production capacity.

- Significant Labor Cost Reduction: The introduction of the automated unstacking system enables clients to significantly reduce manual participation, saving labor costs by 40% – 60%. This not only reduces the operating costs of enterprises but also improves employees’ work efficiency and job satisfaction.

- Accurate Identification and Low Error Rate: Through coordinated work with the robotic arm, the system can accurately identify various turnover boxes of different sizes and patterns, with an extremely low identification error rate of only 0.1%. This ensures the accuracy and reliability of the unstacking process, avoiding production accidents and quality problems caused by misidentification.

In conclusion, the successful implementation of this turnover box unstacking inspection project not only solves the problems encountered by clients in actual production operations but also brings significant economic and social benefits to enterprises. We believe that with the continuous development and application of intelligent technologies, more enterprises will be able to enjoy the convenience and advantages brought by automation and intelligence in the future.