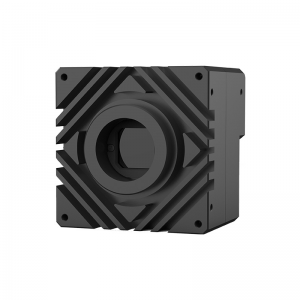

The demand for high-speed, high-precision, large-field-of-view inspection in industrial production is becoming more and more urgent. In the face of the semiconductor, lithium, photovoltaic and other industries, the harsh detection scene, the traditional surface array camera is limited by the frame rate, resolution and spectral response range, it is difficult to meet the high efficiency, high precision inspection needs. MindVision independent research and development of short-wave infrared industrial line array camera MV-GEL20I, localized chip, 2K high resolution, 40kHz ultra-high line frequency and multi-mode triggering technology, to redefine the industrial inspection efficiency and precision boundaries!

The demand for high-speed, high-precision, large-field-of-view inspection in industrial production is becoming more and more urgent. In the face of the semiconductor, lithium, photovoltaic and other industries, the harsh detection scene, the traditional surface array camera is limited by the frame rate, resolution and spectral response range, it is difficult to meet the high efficiency, high precision inspection needs. MindVision independent research and development of short-wave infrared industrial line array camera MV-GEL20I, localized chip, 2K high resolution, 40kHz ultra-high line frequency and multi-mode triggering technology, to redefine the industrial inspection efficiency and precision boundaries!

01

Product Features

·MV-GEL20I uses InGaAs sensor to support 900-1700nm band, integrating visible light and SWIR response bands in one camera, realizing dual-use and significantly expanding the field and range of detection objects.

·Line frequency can be up to 40K, and the software can be set freely.

·Localized design of core components, breaking the dependence on imports and ensuring supply chain security and cost control.

·Support encoder signal frequency division and frequency doubling, and precisely match with the motion platform.

·Support encoder synchronized trigger, photoelectric sensor and encoder combination synchronized trigger and other trigger modes.

·Hardware support for horizontal pixel ROI and automatic splicing of any row in vertical direction (not exceeding the specified upper limit).

02

Spectrograms

03

Product Parameters

|

|

MV-GEL20I |

|

|

Mono/Color |

SWIR |

|

|

Sensor Types |

InGaAs |

|

|

Sensor Size |

12.8× 0.025mm |

|

|

Pixel Size |

12.5umx12.5um |

|

|

Effective Pixels |

2048×1 |

|

|

Sensitivity |

≥0.8A/W |

|

|

Max Line Frequency |

40KHz |

|

|

Exposure Time |

0.005-50ms |

|

|

Trigger Mode |

Continuous/software trigger/frame trigger/line trigger/ Maximum Line Frequency Conditional Line Trigger |

|

04

Application Cases

Hidden crack detection in photovoltaic panels:

Crystalline silicon solar cells are produced with defects that affect efficiency and lifetime such as hidden cracks and scratches, which are usually difficult to detect with the naked eye or visible light. Using electroluminescence (EL) and photoluminescence (PL) properties, the cell can be made to emit short-wave infrared light by applying a positive bias or laser irradiation. The luminescence of the defective area is different from that of the normal area, so a short-wave infrared camera can be used to detect the cell in the excited state and effectively identify internal defects.

05

Product Applications

PCB Inspection

Photovoltaic Panel Inspection

Flat Panel Display Inspection

Metal Detection

Plastic Inspection

Printing Industry Testing